Can Shooter

Popping balloons is all well and good, but for added impact the Evil Genius also likes to shoot cans off the wall with his ray gun. Again, there is some deception going on here. The can is a “special” can with some electronics in it. When the beam from the laser hits the phototransistor sensor, a motor swings a weight that hits the side of the can and makes it jump. If the can is carefully balanced, the movement will be enough to make it fall off the surface it is standing on. Figure 5-16 shows the can jumper, which as you might expect just looks like a can full of the Evil Genius’ favorite lunchtime snack. Figure 5-17 shows the schematic diagram for the can jumper. This uses a light sensor in a similar way to the balloon popper. However, in this case, when the laser hits the phototransistor turning on the MOSFET power transistor, rather than heating a

resistor, it turns on a motor that swings an arm around that hits the can. The diode across the motor prevents the high reverse voltages you get when using a motor from destroying the MOSFET

What You Will Need

You will need the components for the can shooter that are listed in the Parts Bin. You do not usually get much information about a small DC motor when buying one. Often, all you get is its nominal voltage. The author found his motor in a local electronics store for a few dollars. You may also find one as part of a scrap toy or an educational motor kit.

Look for a motor about the same size as the one shown in Figure 5-21 later in the chapter. Chances are it should have a similar amount of power. A 4 6V motor should be fine even though we are going to momentarily power it from 9V. It should not have time to burn out for the small fraction of a second it is on. However, do not be tempted to buy a lower voltage than this because you may well burn it out

The battery is a rechargeable 9V PP3 battery. There are good reasons for using a rechargeable battery here. The motor is likely to draw several amps, the battery will become dead quite quickly, and it is greener and more economical to recharge rather than replace. The expanded packing material is going to be used to diffuse the light from the laser. Look for something that will allow light to pass but diffuse it like frosted glass. We also use this useful material in Chapters 7 and 10, which focus on a laser beam alarm and laser voice transmission.

All the components, including the motor and battery, are mounted onto a piece of perforated prototyping board. This board is like stripboard, but without the strips of copper. It’s just a board with holes drilled into it at a pitch of 0.1 inches. It provides a useful framework to which the components can be attached. Because the motor swings upward, gravity will take care of returning the arm to its resting position, making it ready for the next shot. The design has a micro-switch at the top of the board so the can is turned on when the lid is put in place. Since the lid also blocks out the light to prevent the can jumper from being activated by ambient light, this works well.

Step 1. Cut the Perforated Board

First, find an empty one-pound (450 g) food can. The type with a ring-pull top is needed since it is structurally stronger after it has been opened and has far fewer sharp edges on which to cut yourself. The exact dimensions of cans vary, so you will need to get the length of the perforated board to make an exact fit with your can. The external dimensions of the Evil Genius’ can were 4(1/4)*3 diameter (108mm with a diameter of 75mm). Cut the perforated board with scissors so it is the right length to fill the can from top to bottom. The width is less critical, meaning the width of 1(15/16) inches (49mm) shown in Figure 5-19 should be fine unless you have a very unusually shaped can. The board should be a snug fit top to bottom

Step 2. Build the Arm Assembly

Electric motors usually just end in a metal shaft. The way we attach the arm to the shaft is to use a screw terminal block as our arm. We can just pop the shaft into one of the terminal connectors and tighten the screw. The terminal block strips usually come with ten or more connections in a strip. We only need five, but they can be easily cut into a section of five, using a knife. The terminal block is reasonably heavy so as to provide some momentum to be transferred into the

can. We help this along with a nail, which will also strike the screw. The whole arrangement is shown in Figure 5-20. One of the nails is going to be bent at right angles about half an inch (12mm) from its end. This will strike the self-tapping screw fitted at the right place on the perforated board. The screw will allow the stop point of the arm to be adjusted so it is past the tipping point and will fall back after the can has been shot. The other terminals of the block can be used to attach more weight to the arm. There is, however, a trade-off between the amount of weight on the arm and how fast it moves. So experiment to see what suits your motor best.

Step 3. Attach the Motor

Attach the arm to the motor and position the motor halfway up the perforated board. You now need to mark where the bent nail will hit the perforated board, because we are going to make a hole there so we can fit the self-tapping screw.

Be careful when drilling the perforated board, because it is easy to break if the drill “digs in” to one of the perforations. Choose a drill bit that is just slightly smaller than the diameter of the self-tapping screw. Once the screw is in place, find just the right place for the motor to fit so the nail hits it dead position, make a note of which terminal on the motor was positive. If it just kind of twitches a bit, then try the battery the other way around. At this point, you can also experiment with different weights on the arm to see what works best for your motor

Step 4. Add the Electronics

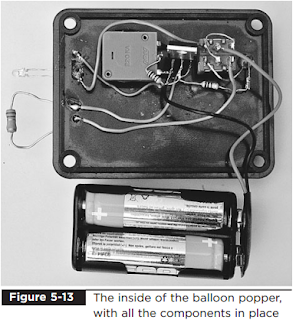

We can now fit the components to the perforated board. The component leads are pushed in from the top of the board and connected together on the back of the board using the component leads and wire. Figure 5-23 shows the wiring diagram

Push all of the components into place and then use Figure 5-23 as a reference to connect up the components. The front of the completed board is shown in Figure 5-24, while Figure 5-25 shows the back of the board. Take particular care to get the phototransistor the correct way around. Check its data sheet, but the longer lead is normally the emitter and the shorter lead the collector. The collector goes to the positive 9V supply. Glue the battery clip perpendicular to the board, as shown in Figure 5-24. When connecting wires to the motor, make sure you connect the positive power supply to the connection you found to be positive in the test at the end of the previous section. We can now test everything before we move onto the final stage of fitting it all into the can. While in the can, the phototransistor will be in very low light, so we need to do this testing in fairly low light to prevent the phototransistor from being turned on all the time. We can also turn the preset variable resistor to its most clockwise position to make the sensor as insensitive as possible. Connect everything up and put the arm in its resting place. If the motor is activated, then disconnect the battery immediately and check everything. Remember, if the motor is left on but is unable to move, it may burn out. Now shine the laser (or any light) onto the phototransistor and the arm should fly up to the top position.

Step 5. Prepare the Can

The first thing we need to do is consume the contents of the can and clean it out thoroughly. If the can contains a food that is not to the liking of the Evil Genius (dog food, for instance), it can be fed to a minion since the Evil Genius believes it’s a crime to waste food. The can should be of the

Popping balloons is all well and good, but for added impact the Evil Genius also likes to shoot cans off the wall with his ray gun. Again, there is some deception going on here. The can is a “special” can with some electronics in it. When the beam from the laser hits the phototransistor sensor, a motor swings a weight that hits the side of the can and makes it jump. If the can is carefully balanced, the movement will be enough to make it fall off the surface it is standing on. Figure 5-16 shows the can jumper, which as you might expect just looks like a can full of the Evil Genius’ favorite lunchtime snack. Figure 5-17 shows the schematic diagram for the can jumper. This uses a light sensor in a similar way to the balloon popper. However, in this case, when the laser hits the phototransistor turning on the MOSFET power transistor, rather than heating a

resistor, it turns on a motor that swings an arm around that hits the can. The diode across the motor prevents the high reverse voltages you get when using a motor from destroying the MOSFET

Step 2. Build the Arm Assembly

What You Will Need

You will need the components for the can shooter that are listed in the Parts Bin. You do not usually get much information about a small DC motor when buying one. Often, all you get is its nominal voltage. The author found his motor in a local electronics store for a few dollars. You may also find one as part of a scrap toy or an educational motor kit.

Look for a motor about the same size as the one shown in Figure 5-21 later in the chapter. Chances are it should have a similar amount of power. A 4 6V motor should be fine even though we are going to momentarily power it from 9V. It should not have time to burn out for the small fraction of a second it is on. However, do not be tempted to buy a lower voltage than this because you may well burn it out

The battery is a rechargeable 9V PP3 battery. There are good reasons for using a rechargeable battery here. The motor is likely to draw several amps, the battery will become dead quite quickly, and it is greener and more economical to recharge rather than replace. The expanded packing material is going to be used to diffuse the light from the laser. Look for something that will allow light to pass but diffuse it like frosted glass. We also use this useful material in Chapters 7 and 10, which focus on a laser beam alarm and laser voice transmission.

All the components, including the motor and battery, are mounted onto a piece of perforated prototyping board. This board is like stripboard, but without the strips of copper. It’s just a board with holes drilled into it at a pitch of 0.1 inches. It provides a useful framework to which the components can be attached. Because the motor swings upward, gravity will take care of returning the arm to its resting position, making it ready for the next shot. The design has a micro-switch at the top of the board so the can is turned on when the lid is put in place. Since the lid also blocks out the light to prevent the can jumper from being activated by ambient light, this works well.

Step 1. Cut the Perforated Board

First, find an empty one-pound (450 g) food can. The type with a ring-pull top is needed since it is structurally stronger after it has been opened and has far fewer sharp edges on which to cut yourself. The exact dimensions of cans vary, so you will need to get the length of the perforated board to make an exact fit with your can. The external dimensions of the Evil Genius’ can were 4(1/4)*3 diameter (108mm with a diameter of 75mm). Cut the perforated board with scissors so it is the right length to fill the can from top to bottom. The width is less critical, meaning the width of 1(15/16) inches (49mm) shown in Figure 5-19 should be fine unless you have a very unusually shaped can. The board should be a snug fit top to bottom

Step 2. Build the Arm Assembly

Electric motors usually just end in a metal shaft. The way we attach the arm to the shaft is to use a screw terminal block as our arm. We can just pop the shaft into one of the terminal connectors and tighten the screw. The terminal block strips usually come with ten or more connections in a strip. We only need five, but they can be easily cut into a section of five, using a knife. The terminal block is reasonably heavy so as to provide some momentum to be transferred into the

can. We help this along with a nail, which will also strike the screw. The whole arrangement is shown in Figure 5-20. One of the nails is going to be bent at right angles about half an inch (12mm) from its end. This will strike the self-tapping screw fitted at the right place on the perforated board. The screw will allow the stop point of the arm to be adjusted so it is past the tipping point and will fall back after the can has been shot. The other terminals of the block can be used to attach more weight to the arm. There is, however, a trade-off between the amount of weight on the arm and how fast it moves. So experiment to see what suits your motor best.

Step 3. Attach the Motor

Attach the arm to the motor and position the motor halfway up the perforated board. You now need to mark where the bent nail will hit the perforated board, because we are going to make a hole there so we can fit the self-tapping screw.

Be careful when drilling the perforated board, because it is easy to break if the drill “digs in” to one of the perforations. Choose a drill bit that is just slightly smaller than the diameter of the self-tapping screw. Once the screw is in place, find just the right place for the motor to fit so the nail hits it dead position, make a note of which terminal on the motor was positive. If it just kind of twitches a bit, then try the battery the other way around. At this point, you can also experiment with different weights on the arm to see what works best for your motor

Step 4. Add the Electronics

We can now fit the components to the perforated board. The component leads are pushed in from the top of the board and connected together on the back of the board using the component leads and wire. Figure 5-23 shows the wiring diagram

Push all of the components into place and then use Figure 5-23 as a reference to connect up the components. The front of the completed board is shown in Figure 5-24, while Figure 5-25 shows the back of the board. Take particular care to get the phototransistor the correct way around. Check its data sheet, but the longer lead is normally the emitter and the shorter lead the collector. The collector goes to the positive 9V supply. Glue the battery clip perpendicular to the board, as shown in Figure 5-24. When connecting wires to the motor, make sure you connect the positive power supply to the connection you found to be positive in the test at the end of the previous section. We can now test everything before we move onto the final stage of fitting it all into the can. While in the can, the phototransistor will be in very low light, so we need to do this testing in fairly low light to prevent the phototransistor from being turned on all the time. We can also turn the preset variable resistor to its most clockwise position to make the sensor as insensitive as possible. Connect everything up and put the arm in its resting place. If the motor is activated, then disconnect the battery immediately and check everything. Remember, if the motor is left on but is unable to move, it may burn out. Now shine the laser (or any light) onto the phototransistor and the arm should fly up to the top position.

Step 5. Prepare the Can

The first thing we need to do is consume the contents of the can and clean it out thoroughly. If the can contains a food that is not to the liking of the Evil Genius (dog food, for instance), it can be fed to a minion since the Evil Genius believes it’s a crime to waste food. The can should be of the